DER SCHLÜSSEL ZUM ERFOLG LIEGT DARIN, DIE GESAMTE PROZESSKETTE IM BLICK ZU HABEN

Für Sie entwickeln wir eine breite Palette von Produkten und Dienstleistungen entlang der gesamten Prozesskette.

Damit sparen Sie Material, Energie, Zeit und Geld!

SIMULATION

Daher ist es notwendig, Simulationen einzusetzen um:

• Den Materialverbrauch zu reduzieren

• Energie einzusparen

• Zykluszeiten zu verringern

• Qualität zu produzieren

Wenn Sie selbst simulieren möchten oder einen Dienstleister suchen – in uns haben Sie den richtigen Partner.

Lesen Sie mehr über die Vorteile der Simulation oder fragen Sie direkt nach einer Simulation für Ihr aktuelles Projekt.

Erste Ergebnisse nach 1-2 Werktagen

INDUSTRIALISIERUNG

Mehr denn je steht der Begriff heute für einen schnellen Wechsel in unserer Arbeitswelt.

Digitalisierung in all ihren Facetten von IoT über Machine learning bis hin zu künstlicher Intelligenz bestimmt die Zukunft.

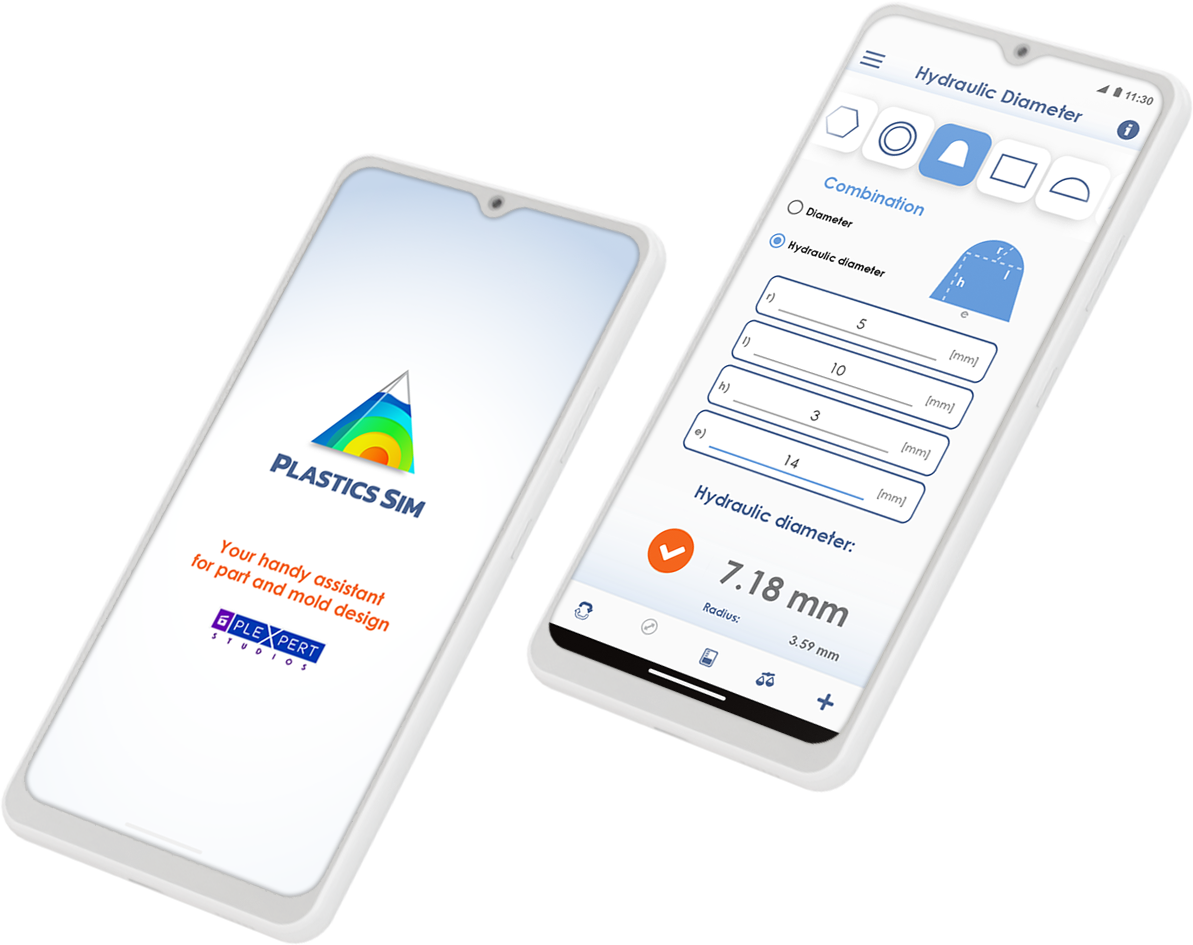

Wir verstehen die gesamte Prozesskette der Herstellung von Kunststoffteilen.

Nutzen Sie unsere Hard- und Software in den einzelnen Stufen der Prozesskette, um Ihr Leben einfacher zu machen.

Nehmen Sie sich etwas Zeit, um mehr darüber zu erfahren.

QUALIFIKATION

Um den maximalen Nutzen aus neuen Technologien zu ziehen, müssen wir ständig lernen.

Dies kann in Präsenzveranstaltungen, persönlichen Schulungen oder Online-Kursen geschehen.

Jede Form der Schulung hat Ihre Vorzüge.

Auch wenn der Schwerpunkt auf individuellen Online Kursen liegt, bieten wir persönliche Schulungen und Präsenzveranstaltungen an.

Lesen Sie, welche Vorteile sich daraus für Sie ergeben.

STUDIOS

Egal ob wir Konstrukteure, Werkzeugmacher oder Spritzgießer sind,

wir alle müssen unsere Fähigkeiten und Möglichkeiten anderen mitteilen.

Dadurch erweitern wir unseren Bekanntheitsgrad und finden neue Kunden.

Für Sie und Ihr Unternehmen finden wir die richtigen Worte, Bilder und Animationen.

Dabei schöpfen wir aus einem über Jahre gewachsenen Pool und dem Wissen der Branche.

Welche Möglichkeiten sich daraus für Sie ergeben erfahren Sie, wenn Sie weiter lesen.

PLEXPERT ist ein multinationales Unternehmen mit Experten aus allen Bereichen der Kunststoff-Branche.

Unsere Produkte und Dienstleistungen nutzen Firmen in der ganzen Welt.

Nutzen auch Sie unser über viele Jahre gesammeltes Wissen und unsere praktische Erfahrung, die in zahllosen Projekten geschärft wurde.

Sparen Sie wertvolle Ressourcen ein und machen Sie Ihr Leben einfacher durch unsere Produkte und Dienstleistungen.

Von Anwender für Anwender in einem starken Verbund mit Partnern, die wir Ihnen gerne vorstellen.